Base channels with extra height for heated bench channels. 4″ solid concrete blocks are laid as a base to raise the firebox up to a nice sitting height.

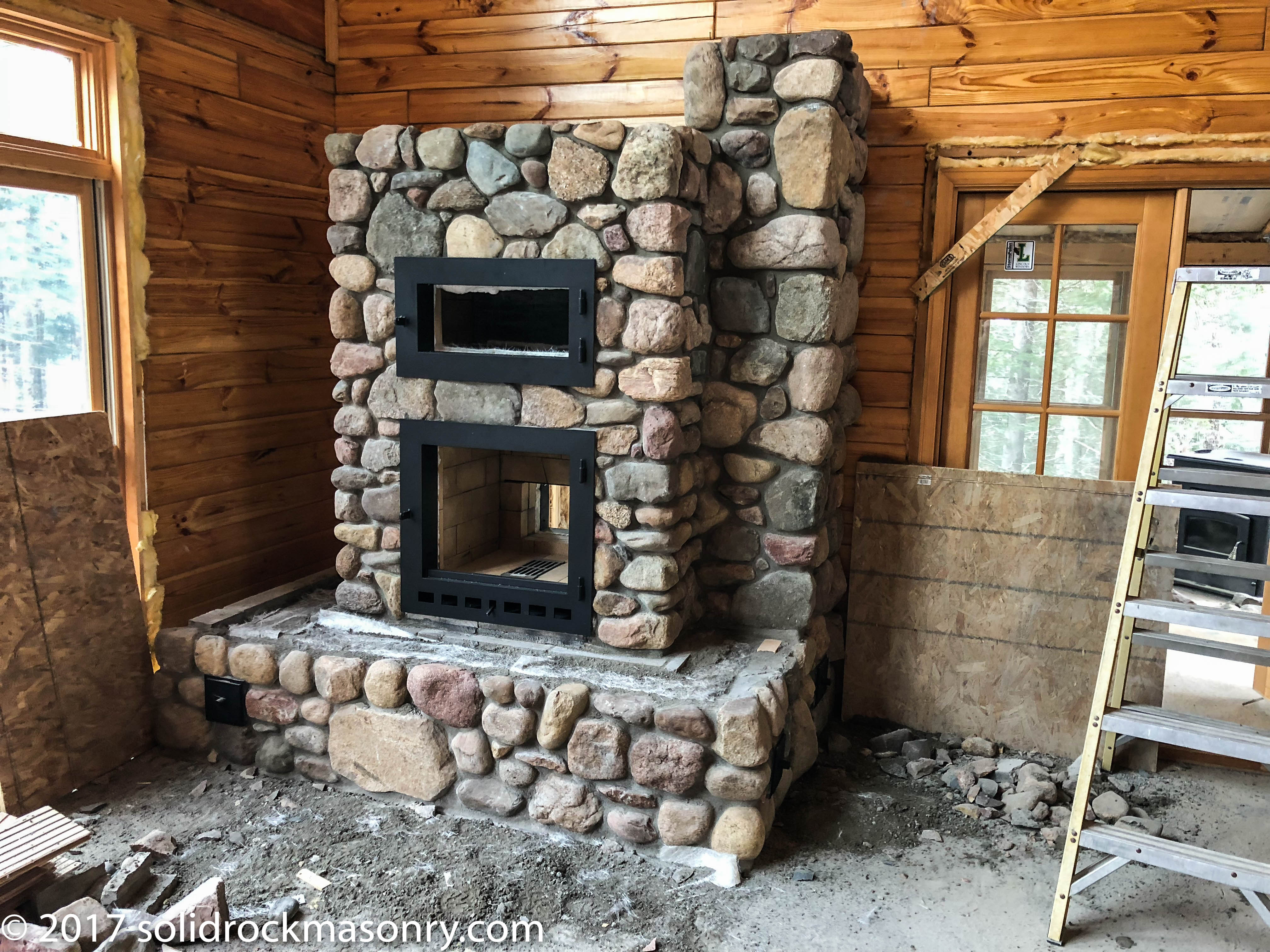

This is one of our SR-22HWO Hybrid masonry heater cores with a white oven being built. Our client wanted to be able to see the fire and be able to see and load the fire from 2 rooms so we designed a smaller door on the back side of the heater to facilitate this.

Outer wall of the firebox being built up with the smaller loading door built into the back of the firebox.

Back oven door has our stainless steel and mild steel combo lintel and an arched keystone for strength.

Finished core and replaceable firebox floor being set.

These are our original smaller draft channels being used here. The hole on the bottom is the exit into the heated bench system.

Fiberglass matte expansion material in place.

4″ block base set for heated hearth. We also set 4″ block up along core to get to height for setting stone at top of hearth level

Local granite fieldstone being set around the core. 8″ round clay chimney is set and being stoned around also. We fill the space between the heater core and chimney with brick and concrete block to fill the space solid for heat transfer.

We used 4″ solid concrete blocks on the back side of this heater for the heater mass and for code purposes. The client will finish the back side of the heater with tile. We lay the 4″ CMU first and set brick ties into each course to tie into the stone being built. This ties the 2 walls together. The 2×4 (2×6 lumber ripped to 4″) piece of wood is a temporary spacer set in place to be able to lay the wing wall of stone to the wood wall. This piece of lumber is removed after stone is laid. There is still a 4″ air space behind the chimney for code purposes.

This is the end of our part of the stone laying. The owner is ordering granite slabs for the hearth and heater capping slabs to set on his own.